How to Use Smt. SMD Epoxy Adhesive Red glue For PCB Underfill

SMT epoxy adhesive is a liquid which solidifies when it comes into contact with a surface.

There are many uses for SMT epoxy adhesive. It can be used to attach objects to surfaces, or to bond other materials. Because it is not conducive to electricity, it is used often in electronics. It can also provide strong adhesion.

Uses for SMT epoxy adhesive

SMT epoxy adhesive is used for bonding printed circuit boards to substrates. The epoxy adhesive is two-component and room temperature curing.

SMT epoxy adhesive is used for bonding printed circuit boards to their substrate. It is a two-component adhesive that cures at room temperature.

Types

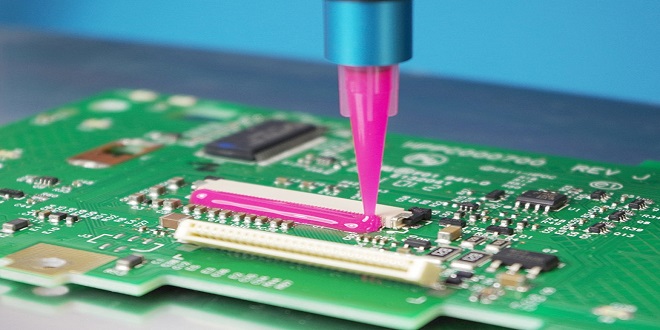

The SMT epoxy glue is an epoxy adhesive used for the assembly of SMT components. SMT epoxy adhesive can either be applied to the PCB surface or to a component. It will adhere to both. You can also apply the SMT epoxy adhesive to an already assembled component, and then reassemble it.

Two parts make up SMT epoxy adhesives: an activator, and a resin. The two components are combined to form a liquid which can be applied using a syringe, brush, or other tools.

you can pay a visit to->https://www.deepmaterialcn.com/

An example of a resin is the SMT epoxy adhesive. It can be used to join two pieces of metal, glass, or plastic.

Apply the epoxy adhesive to one side, then press the opposite side against it. Depending on the purpose of the epoxy adhesive, there are many ways it can be applied. If you’re using the epoxy adhesive to adhere glass, for example, you’ll use a squeegee and spread it evenly on both sides. Then, press the two together with a pressing tool.

An epoxy adhesive is made up of two components: an epoxy resin and hardener. This mixture creates a sticky paste. This paste acts as an adhesive in SMT assembly.

These are the components of epoxy adhesives:

A liquid epoxy resin which cures to a hard solid material when exposed heat or air.

A hardener (curing agent), which is added to the resin to alter its properties and speed up curing.

-Solvents that speed up the epoxy’s cure time and make it easier to use by hand or machine.

Uses

SMT epoxy adhesives can be used in place of solder paste to attach surface mount boards.

After the epoxy is applied to the surface, the component is then placed on top. The epoxy cures at high temperatures and is then permanently attached to the board.

There are two types of epoxy adhesives: conductive and dielectric. Conductive epoxies are less viscous than dielectric, making them more suitable for attaching heat-sensitive components, like power semiconductors.

Epoxy adhesives are used to bond a variety materials. This adhesive is widely used today, even though it has been around for more than 50 years.

Two components make up epoxy adhesives: resin and hardener. The epoxy adhesive is made up of the resin and the hardener. The wide variety of uses for epoxy adhesives include electronics, woodworking and construction.

Discover the essence of crafting captivating magazine content, delving into the art of storytelling and visual aesthetics. Uncover the secrets to engaging readers through compelling narratives and striking imagery, elevating the impact of each page turn. Master the intricacies of magazine creation to resonate with diverse audiences and leave a lasting impression.

SMT epoxy adhesive form

An epoxy adhesive is a type of resin-based adhesive that is used in surface mounting technology. It is made up of an epoxy resin and an amino hardener.

The SMT epoxy adhesive is usually applied to the PCB and then components are added. To cure the adhesive and attach components, the board can be heated.