Guide to CNC Knife Cutting Machines 2023

There are some problems that you might encounter when purchasing a CNC Knife Cutting Machine. This guide might help. Please read on.

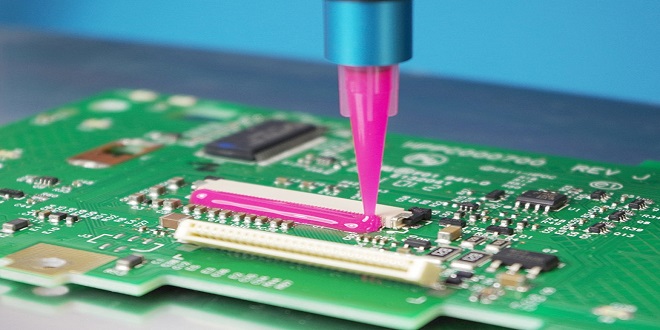

What is CNC knife cutting machine? These machines are used in many industries including aerospace and automotive. These machines can be used for cutting multiple materials such as metal, plastic, wood, and stone. These include:-Cutting sheet steel for body panels and other components-Cutting rubber molds for car doors-Cutting plastic parts dashboards, consoles, and interior trim-Cutting fiberglass exterior body panels

How does a CNC knife cutting machine work?

The computer controls the movement of the cnc knife cutter machine. The computer is equipped with a program that instructs it how to move and how fast it should move. It also tells it what kind of cut it should make.

You can use the program to cut multiple parts or in different patterns. One edge of the knife is used for cutting wood or plastic. The other side is for cutting metal sheets and other materials.

Marking where screws will be installed is a good idea. You can also hold your material down on the table or chuck (which holds your tools) while marking. A cutter is also necessary. This allows you to access the inside of your material and makes it easier to work efficiently.

Consider these factors when buying a CNC knife-cutting machine

The machine’s size and cutting power. The machine’s size and cutting capacity will determine how many materials and parts can be cut simultaneously.

You should specify the type of material you intend to cut using your machine. Certain materials are more difficult than others and require specific tools or blades to properly be cut.

You should consider what material you will use to support your machine’s cutting surface. Certain materials are more susceptible to damage than others when used as cutting beds. You should ensure that any material you intend to use as a support for your workpiece in the cutting process is sufficiently strong.

Your machine’s size. A smaller machine might be better suited for cutting small pieces of metal, plastic or wood than one designed to handle larger pieces.

Your budget for purchasing a new metal cutting machine. There are many options when it comes to purchasing a new machine. Make sure you consider all your needs before making a final decision about the model that will best suit you.

How to effectively use a CNC knife cutting machine

Make sure that the machine is properly assembled and that all cables and pulleys work well.

If applicable, set the tool length at zero

Place the tool in the holder of your CNC knife-cutting machine. Make sure it faces forward.

Turn on your CNC knife-cutting machine by connecting the power supply. This will enable you to test the machine and set it up for use.

To automate a cut from a file that you created using CAD software like SolidWorks or AutoCAD, set up your software program

Safety precautions when using a CNC knife-cutting machine

This will prevent you from getting hurt if the material is thrown at you.

What are the advantages of using a CNC knife-cutting machine? There are many.

It can be used for cutting any material with great precision and accuracy.

It can be used for cutting variety of materials, including wood, plastic, and metal.

It is much easier to use than traditional machines like lathes.

Because it is based on computerized technology, it cuts materials faster and more efficiently than traditional machines like lathes.